Tech Team Builds Automated Garden

September 29, 2017

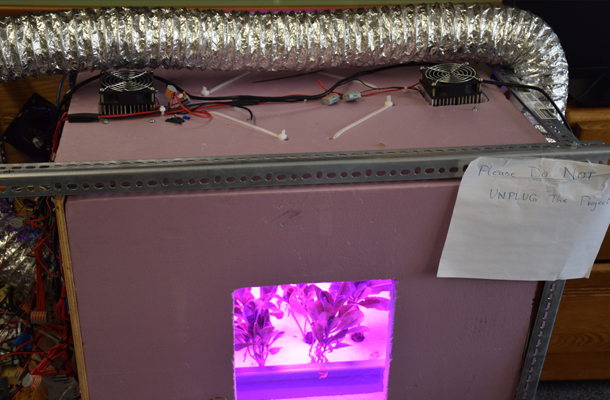

Combining all aspects of STEM (Science, Technology, Engineering, and Math), 6 students created a machine over the summer to help farmers grow produce more efficiently. The machine, nicknamed “D-9”, keeps temperature and humidity constant, creating a controlled, nutritious environment for plants to thrive.

Sophomore Armaan Johal, seniors Anya Li, Regina Kong, and Vasily Tremsin, as well as Campolindo graduates Stone Mao and Ray Diaz worked on the project. “The group came together by doing research at Campolindo, seeing which students had an interest in this kind of technology, taken classes relating to this, if they’re good students generally, and if they had a good team dynamic,” Johal said.

Their goal was to use lessons that they learned in the classroom and apply them to the real world.

The name “D-9” is in reference to club adviser Nita Madra’s classroom. Madra, along with fellow adviser Rene Gillibert, helped support the student team. “Mr. Gillibert helped us with the biology aspect of it, and Ms. Madra was there for robotics and math,” Li added.

“I tried to help a little bit in the construction, just give suggestions to the design. I helped with their understand of photosynthesis, and the actual growing of the plants, so how to germinate the seeds, and how to keep the plants growing,” said Gillibert.

The project was based on ideas by Johal and his dad, who brainstormed ways to bring healthy food to every home in a way that could be transported over seas. “My dad has a really good background with technology, and I really enjoy technology, and I was trying to find a way to better the world, eventually by using technology,” said Johal.

Using Johal and his dad’s ideas, the group decided to build the entire machine by hand.“It took us three months to build the first prototype back in the summer, because we built it from scratch, and so now we want to build more, and donate them in the future,” Li said.

Li described the finished D-9 as “an automated farm, and it’s supposed to be like a personal farm, so it’s like a 3 by 3 by 2 foot box, that you could theoretically put inside of your kitchen, or you could ship it, to say, a desert.”

Once the machine is proven to be advantageous, the group plans to make marketable models.